How Is Aluminum Recycled and What Are the Steps Involved?

Recycling aluminum is a crucial process for sustainability and resource conservation. At Dade Scrap Iron & Metal, we follow a detailed procedure to ensure aluminum is efficiently recycled and repurposed.

Collection and Sorting

The recycling process begins with the collection and sorting of aluminum scrap. At Dade Scrap Iron & Metal, we accept various aluminum items, from cans and foils to old aluminum parts and frames. The first step involves gathering these materials and sorting them by type and quality. Our facility uses advanced sorting technology, including magnets and automated systems, to separate aluminum from other metals and contaminants.

Proper sorting is essential for maximizing the efficiency of the recycling process and ensuring that the aluminum is clean and ready for the next stages. By accurately sorting aluminum scrap, Dade Scrap Iron & Metal helps streamline recycling and maintain high standards of quality.

Shredding, Melting, and Repurposing

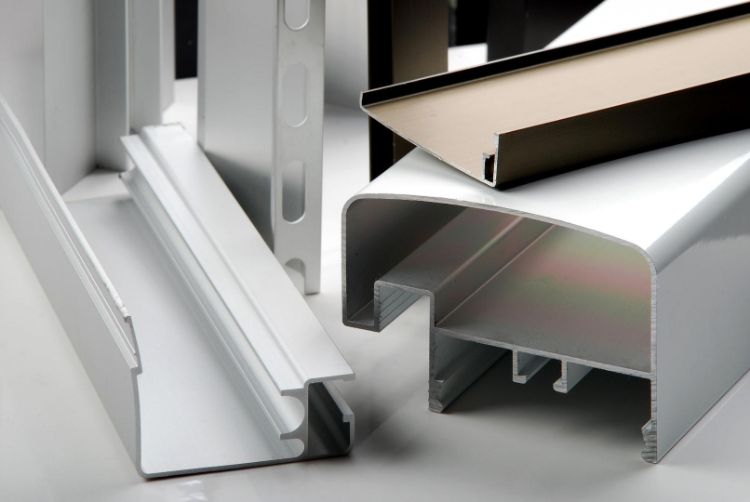

After sorting, the aluminum scrap undergoes further processing at Dade Scrap Iron & Metal. The next step is shredding, where the aluminum is cut into small pieces to facilitate easier melting. The shredded aluminum is then placed in a high-temperature furnace, where it is melted down. This process removes impurities and transforms the aluminum into a molten state. Once melted, the aluminum is poured into molds or cast into large blocks known as ingots. These ingots can then be used to manufacture new aluminum products, such as cans, automotive parts, or building materials.

Recycling aluminum in this manner conserves energy, reduces environmental impact, and supports a circular economy. At Dade Scrap Iron & Metal, we ensure that every step is conducted efficiently to maximize the environmental and economic benefits of aluminum recycling.